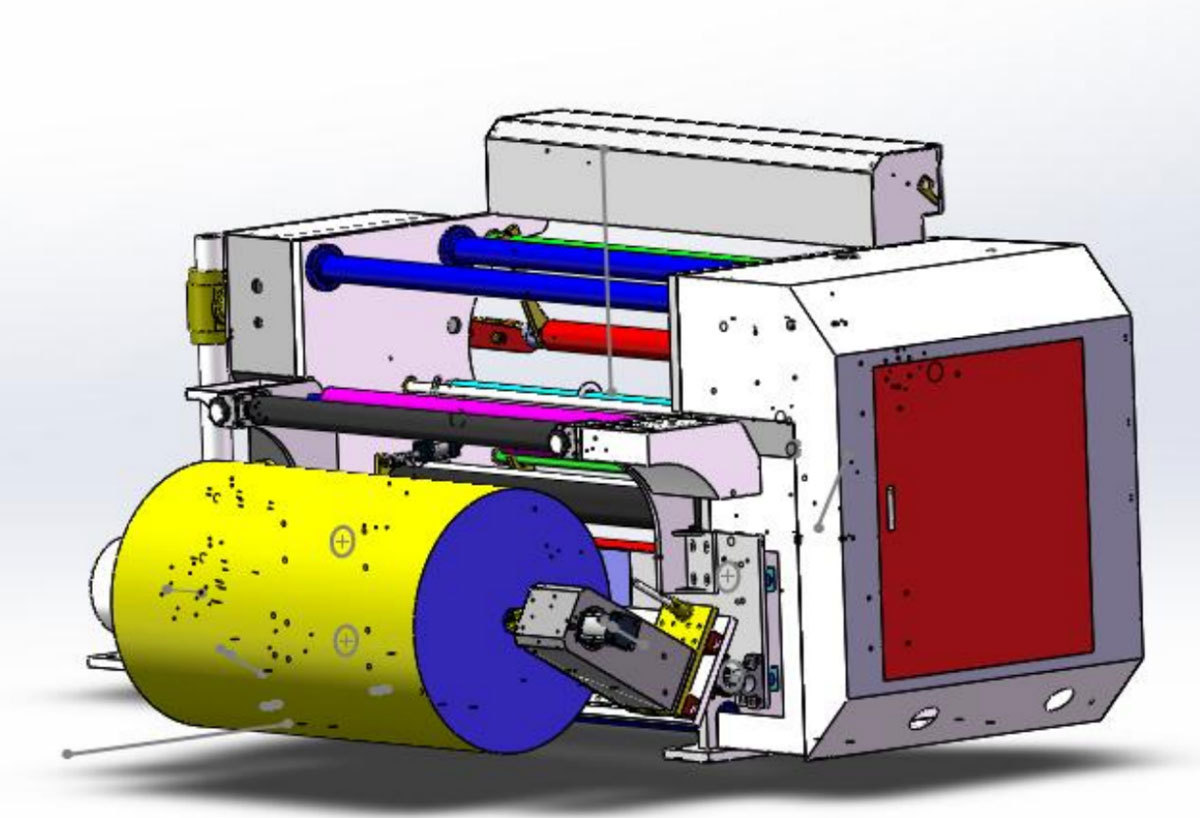

هذه الآلة مناسبة لورق الكرافت الذي يقلب الورق بمختلف لفائف الحز إلى لفات أصغر ، PET OPP CPP PE غير المنسوجة القماش PVC والمواد البصرية فيلم لفة الورق والمواد المختلفة.

يتطلب استخدام PLC المستورد لتحقيق وظائف تحكم دقيقة ومستقرة فقط إدخال سمك المواد الخام وقطر النطاق العريض والسرعة.

Main technical parameters:

|

Material width |

1300mm |

|

Material diameter |

800mm |

|

Winding diameter |

600mm |

|

Papertube inner hole |

3 # 6 # |

|

Slitting speed |

10-300m/min |

|

MIN SPLIT |

25-1300MM |

|

Total power |

15 kw |

|

Mechanical dimensions |

1890X2700X1600 |

|

PLC |

Mitsubishi, Japan |

|

Servo Motor |

Danma China |

|

Touch screen |

Weinview Taiwan |

|

Edge correction device |

Pausource Taiwan |

|

Cylinder |

Airtac Taiwan |

|

Bearing |

NSK Japan |

Characteristics

A . Host part

1. The equipment host adopts steel plate material as the center for secondary processing and shaping treatment

2. The transmission spindle is machined from seamless steel pipes and has a surface hardening and dynamic balancing treatment

3. The material guide roller is completed with aluminum alloy guide roller and rubber roller

4. The transmission mode of the 4 main engines is synchronous belt synchronous wheel transmission

B. Material discharge section

1. The feeding mechanism is a connected feeding rack

2. The material is automatically loaded using shaftless hydraulic pressure, which effectively saves labor and is convenient and simple to operate

3. Equipped with a set of adjustable deflection rod device that can be adjusted through a handwheel

4. Magnetic powder brake braking is used for unwinding

5. Edge correction adopts thepausource brand to achieve edge tracking of materials(BST or other brands customize plz contact sales staff)

C. Material receiving section:

1. Receiving shaft, 3 inches slip shaft, 2 pieces

2. The locking method is controlled by automatic inflation method

3. Cutting knives are divided into 10 flat knives using a flat knife

4. Equipped with a set of waste blowing edge device

5. Sets of finished subframes

Equipped with infrared ray to effectively improve production efficiency by positioning the paper tube

4.Electrical parts

1. Host adopts 1 frequency converter

2. Main machines, 1 Danma motor

3. Winding using 2 frequency converters

4. Danma motors for 4 hosts

5. LPC uses analog control to drive servo motors

Using imported PLC to achieve precise and stable control functions only requires input of raw material thickness, broadband diameter, and speed.

All subsequent tasks are automatically calculated by the computer.

Random Accessories:

1 set of Allen wrenches 5 oil gun

2 adjustable wrench 6 air gun

3 Slotted screwdriver 7 Air nozzle

4 Phillips screwdriver